Driver Shaft is also called drive shaft (CVJ), which connects the differential with the drive wheels. The half shaft is the shaft that transmits torque between the gearbox reducer and the driving wheel. There is a universal joint (U/JOINT) at the inner and outer ends of the shaft, which is connected to the reducer gear and the inner ring of the hub bearing through the spline on the universal joint. .

image

The role of automobile axle shaft

The half shaft transfers the power from the differential to the left and right driving wheels.

The half shaft is a solid shaft that transmits large torque between the differential and the drive axle. Its inner end is generally connected with the side gear of the differential by a spline, and the outer end is connected to the drive by means of flange disc or spline. The wheel shells of the wheels are connected.

Automobile half shaft structure

The half shaft is used to transmit power between the differential and the drive wheels. The half shaft is the shaft that transmits the torque between the gearbox reducer and the driving wheel. Generally, it used to be mostly solid. Because the hollow shaft is easier to control unbalanced rotation, now, many cars use a hollow shaft, and the half shaft has a universal shaft at its inner and outer ends. The U/JOINT is connected to the gear of the reducer and the inner ring of the hub bearing through the spline on the universal joint.

Image] [image

Automobile axle shaft classification

The semi-axles commonly used in modern cars are classified into full-floating and semi-floating according to their different supporting types. (There are also three types, namely full-floating, 3/4-floating, and semi-floating)

Full floating half shaft

The semi-axle that only bears torque when working, and does not bear any force or bending moment at its two ends is called a full-floating semi-axle. The outer flange of the half shaft is fastened to the hub with bolts, and the hub is mounted on the half shaft sleeve through two bearings far apart. Structurally, the inner end of the full-floating half shaft is made of splines, the outer end is made of flanges, and there are several holes on the flanges. Because of its reliable work, it is widely used in commercial vehicles.

3/4 floating half shaft

In addition to bearing the full torque, it also bears a part of the bending moment. The most prominent structural feature of the 3/4 floating half shaft is that there is only one bearing at the outer end of the half shaft, which supports the wheel hub. Due to the poor supporting rigidity of a bearing, in addition to the torque, this kind of semi-axle also bears the bending moment caused by the vertical force, driving force and lateral force between the wheel and the road surface. 3/4 floating half shafts are rarely used in automobiles.

Semi-floating half shaft

The semi-floating half shaft is directly supported on the bearing located in the inner hole of the outer end of the axle housing with a journal close to the outer end. The end of the half shaft is fixedly connected to the hub with a journal and a key with a tapered surface, or directly connected with a flange The wheel disc and the brake hub are connected. Therefore, in addition to transmitting torque, it must also bear the bending moment caused by the vertical force, driving force and lateral force transmitted by the wheel. Semi-floating semi-axle has simple structure, low quality, and low cost, so it is applied to passenger cars and some vehicles of the same use.

image

Common faults of half shaft

If the car owner hears abnormal noises from the direction of the half-axis of the car while driving, he should stop and check carefully.

Under the action of long-term torsional fatigue and impact, the semi-axles of automobiles are prone to bend, twist and break, and spline teeth wear or skew. For the fracture of the half shaft, there are the following morphological types:

(1) The half-shaft hair blue plate falls off or cracks;

(2) The half-shaft shaft is flush and fractured;

(3) Spiral fracture of the half shaft;

(4) Mixed fractures and cracks in the shaft of the half shaft;

(5) The spline of the half shaft is broken;

(6) Fractures and cracks in other topography of the half shaft.

If these conditions occur, the car should be driven to the auto repair shop or 4S shop for repair or replacement in time.

‰∏éÊ≠§ÂéüÊñáÊúâÂÖ≥ÁöÑÊõ¥Â§ö‰ø°ÊÅØ˶ÅÊü•ÁúãÂÖ∂‰ªñæòªËØë‰ø°ÊÅØÂQåÊÇ®ÂøÖÈ°ªËæìÂÖ•Áõ∏Â∫îÂéüÊñá]]>

The automobile half shaft is also called the drive shaft, which is the shaft that connects the differential and the drive wheels.

The semi-shaft is the shaft that transmits torque between the gearbox reducer and the driving wheel. There is a universal joint (U/JOINT) at the inner and outer ends, respectively, which are connected to the reducer gear and the inner ring of the hub bearing through the spline on the universal joint. .

The role of automobile axle shaft

The half shaft transfers the power from the differential to the left and right driving wheels.

The half shaft is a solid shaft that transmits large torque between the differential and the drive axle. Its inner end is generally connected with the side gear of the differential by a spline, and the outer end is connected to the drive through a flange or spline. The wheel shells of the wheels are connected.

The half shaft structure is different due to the different structure of the drive axle. The half shaft in the non-disconnected drive axle is a rigid full shaft;

The half shafts in the steering drive axle and the split drive axle are segmented and connected by universal joints.

Automobile half shaft structure

The half shaft is used to transmit power between the differential and the drive wheels. The half shaft is the shaft that transmits the torque between the gearbox reducer and the drive wheel. Generally, it used to be mostly solid. Because the hollow shaft is easier to control unbalanced rotation, now, many cars use a hollow shaft, and the half shaft has a universal shaft on its inner and outer ends. The U/JOINT is connected to the gear of the reducer and the inner ring of the hub bearing through the spline on the universal joint.

Types of car axle shafts

The semi-axles commonly used in modern cars are classified into full-floating and semi-floating according to their different supporting types.

The full-floating semi-axle only transmits torque, and does not bear any reaction force or bending moment. Cooperating with the independent suspension, it is beneficial to improve the comfort of the vehicle, so it is widely used in various vehicles. The full-floating half-shaft is easy to disassemble and assemble. Only by unscrewing the fixing bolts of the half-shaft during maintenance, the half-shaft can be drawn out. The wheels and axle housing can still support the car, thus bringing convenience to car maintenance.

The semi-floating half shaft not only transmits torque but also bears all reaction forces and bending moments. Its supporting structure is simple and low in cost, and it is mainly suitable for pickup and SUV vehicles that do not require high comfort. However, this kind of half-shaft support is troublesome to dismantle, and if the half-shaft breaks during driving, it is easy to cause the risk of wheels flying off, which is a form that is about to be eliminated.

ÂèëÈÄÅÂèçȶ?br />ÂéÜÂè≤ËÆ∞ÂΩï

The semi-axle is an important part of the automobile drive system. When the vehicle is running, the wheel traction, braking force and lateral force can easily cause the semi-axle to produce large bending, torsion, and shear stress. When the car is overloaded and driving at high speed on poor roads, the violent bumps and vibrations will affect the semi-axle; moreover, excessive acceleration and deceleration and frequent use of emergency braking make the semi-axle easy to bend, deform and break. If this half shaft is broken and it makes a noise during driving, it is necessary to stop for maintenance.

When there is a problem with the half shaft, how to repair it?

(1) The half shaft should be inspected for hidden damage, and no cracks in any form should exist.

(2) The half-shaft spline should have no obvious torsion deformation.

(3) Based on the axis of the half shaft, the radial runout error of the unmachined cylinder in the middle of the half shaft must not be greater than 1.3mm; the radial runout error of the outer cylindrical surface of the spline must not be greater than 0.25mm; the inner side of the half shaft flange The runout error of the end face shall not be greater than 0.15mm. If the radial runout exceeds the limit, it should be corrected by cold pressing; if the end face runout exceeds the limit, the end face can be turned for correction.

(4) The increase in backlash of the half shaft spline shall not be greater than 0.15mm compared with the original factory regulations.

(5) The following inspections should also be carried out on the half-shaft assembly (with constant velocity joints on both sides) of front-wheel drive vehicles:

‚ëÝThe outer end ball cage type constant velocity universal joint should have no radial clearance by hand inspection, otherwise it should be replaced.

‚ë°The inner constant velocity universal joint can slide in the axial direction, but there should be no obvious radial clearance, otherwise it should be replaced with a new universal joint.

③Check whether the dust cover is aging and cracked, and whether the clamp is effective and reliable. If one part of the dust jacket or clamp fails, a new one should be replaced. Otherwise, it may cause abnormal wear of the universal joint due to the complete leakage of grease, and make the half shaft work abnormally or even make the half shaft scrapped.

If car owners find these problems with the car's half axle, they should go to the auto repair shop or 4S shop for maintenance in time to ensure driving safety!

]]>

The dust cover of the drive shaft of the front-wheel drive vehicle is easily broken during the life span. If you find it late, you need to replace it and it is expensive. Therefore, if you are in an older car, please be careful not to pay attention to abnormal sounds and check carefully.

What caused the damage to the dust cover of the drive shaft?

The output of the engine is transmitted from the transmission to the wheels through a rod called the drive shaft. In front-wheel drive and four-wheel drive vehicles, the front wheels are driven, but the steering system must be turned off, so the drive shaft will bend sharply. There are rubber boots covering this.

These guards are called drive shaft guards, but because they are made of rubber, they may harden or crack, causing breakage. Discovery later can damage the drive shaft itself, which can be expensive. Before that, we hope to find it early

What is a drive shaft?

Where is the drive shaft? If you don’t know, look under the bumper and observe the bottom of the tire. From the middle of the car, you can see an iron rod extending towards the center of the wheel. This is the drive shaft. But maybe, it is an FF (front wheel drive) car or a 4WD (four wheel drive car).

Nowadays, front-wheel drive vehicles are very common, but in the past they were rare. The practical application of front-wheel drive vehicles seems to be difficult because it is necessary to drive a shaft with a large steering angle when steering the tire.

FR (rear wheel drive vehicle) also has an axle, which is used to drive the differential between the rear wheels to drive the wheels, but this only needs to follow the vertical movement of the suspension, and the angle is not large if the rear suspension is not independent For example, a commercial vehicle is stored in a box and cannot be seen from the outside, but this type does not have the function of bending the shaft itself.

What happens if the dust cover is cracked? Found before the abnormal noise

The curved part of the drive shaft is called a constant velocity joint, but it needs to be lubricated with grease and sealed with a rubber bellows. This is the drive shaft cover. Every time you turn the steering gear, this part will bend. Although the car is a new car, as it ages, the rubber itself will harden and the bellows valley will tear.

If this happens, the grease inside will be scattered due to the centrifugal force of the rotation, making it impossible to lubricate. In addition, if dust or splashes are in operation, they may bite into the joints or cause grease to flow and cause rust.

In this case, the motion of the joints will become very poor, and if you turn the steering wheel while driving, you will start to hear strange sounds. I think unless you have a lot of suggestions, it will not break (it may break in sports sports), but it will be very unpleasant. In addition, if the sound starts to appear, even if grease is added again, it may leave scratches inside and may not be repairable. Therefore, if the boot breaks, what is the life span of the drive shaft dust cover that needs to be repaired as soon as possible?

The expected life of the drive shaft dust jacket will vary depending on the environment and luck, so it is difficult to say, but at least 50,000 kilometers in 5 years? I think it's fine. If you don't turn the steering wheel, you will not feel pressure, so driving at high speed will not cause much damage to the distance. On the other hand, if you often drive in a narrow alley or turn the steering device completely left or right when parking, you can say that this is a narrow state.

In addition, recently there are resin dust boots that are not made of rubber, and the possibility of breaking is extremely low.

We sometimes have to look down

However, there is no function to let you know that the dust cover is damaged. The only way to ensure that the constant velocity joint is not damaged is to perform a visual inspection. I think it's nice to see that the car is new, but if the car is old and the mileage is increasing, if there are signs of rubber cracking, it is best to increase the frequency of inspections.

When the dust boot is completely torn, the grease inside will splash. If there are obvious black spots and dampness on the tire cover, it may be grease that has splashed. This is why sometimes you should check below. You may also find oil leaks around the engine, mission and steering

How to repair the drive shaft? Need to be replaced when damaged

If the rubber of the dust cover is damaged, it can only be replaced with a new one. Because the axle does not break right away, the urgency of repairing outside is very low, but it is better to avoid gravel roads and driving on rainy days. Of course, the sooner the repair, the better.

]]>

Before introducing the half axle, let's first understand how the power of the car is transmitted.

Automobile transmission system

The driving force generated by a car engine has to go through a series of power transmission devices to reach the driving wheels. The power transmission mechanism between the engine and the driving wheels is called the transmission system of the automobile, which is mainly composed of clutches, transmissions, transmission shafts, universal transmissions, main reduction differentials, and half shafts.

The power output by the engine first passes through the clutch, and after the torque and speed are changed by the transmission, the power is transmitted to the final drive through the transmission shaft, and finally the power is transmitted to the driving wheels through the differential and the half shaft.

Half shaft

The half shaft, that is, the constant velocity universal joint assembly, is installed between the differential or end reducer gear and the wheel, and consists of two or one set of constant velocity universal joints, intermediate shafts (core shafts) and other parts. The power of the engine is transmitted to the wheels to drive the car.

The two constant velocity universal joints (also known as ball cages) on the half shaft are divided into inner and outer parts. One end of the outer ball cage is mounted on the automobile hub bearing and is splined on the inner ring of the hub bearing to transmit power. The connection method of the inner ball cage is also through spline engagement, the bearing diameter of the inner ball cage has a support and protection function, and the power is transmitted through the spline and the gear of the reducer.

Anhui Xuancheng Yongjian Machinery Co., Ltd.

Factory Address: Sunbu Town Industrial Zone, Xuancheng City, Anhui Province

Phone: 0563-3188008

Fax: 0563-3188198

Website: www.222tn.com

Email: yjbz999@163.com

The half shaft of the car is made of 40Cr:

1. 40Cr is my country's national standard steel grade, and 40Cr steel is one of the most widely used steels in machinery manufacturing;

2. After quality treatment, it has good comprehensive mechanical properties, good low temperature impact toughness and low notch sensitivity;

3. The quenching effect of steel is good, water quenching can be adjusted to 28ÔΩ?0mm, oil quenching can be adjusted to 15ÔΩ?0mm, this kind of steel is suitable for cyanide and high frequency quenching in addition to treatment;

4. The cutting performance is better. When the hardness is 174ÔΩ?29HB, the relative machinability is 60%. The steel is suitable for making medium-sized plastic molds.

]]>

The half shaft of a car is the transmission shaft. The car needs to turn after walking. The rotation of the wheels on both sides is different. Faster on one side and slower on the other. This requires a differential on the transmission shaft. The differential is a device that allows the wheels on both sides to rotate at different speeds. The half shaft is connected to the differential and then to the wheels.

The two ends of each axle are respectively connected to the wheels and the differential on the side, and the torque and speed distributed by the differential are transmitted to the wheels to drive the wheels to rotate. The rotational speed transmitted by half shafts of general construction machinery such as loaders and cranes will be further decelerated by the wheel-side reducer to increase the torque and make the wheels have a stronger driving force. The wheel speed reducer is the planetary gear reducer.

The drive shaft uses two half shafts is designed to improve the vehicle's turning performance.

]]>

Where is the structural bearing capacity of the automobile half shaft?

We all know that the application of this product in automobiles is very important, and is a very important part. This product is also divided into different types. Different products have different performances. It is divided into half-floating half-axis and full-floating half-axis. So what are the differences between the two types? These two, the form, their difference lies in the hub here. To put it simply, the full complex is more complicated. Moreover, this type of semi-axle has a greater bearing capacity. It can withstand the axial force of outward and inward, and it can also stabilize the wheel and various torques very well. , Its structural endurance is even higher.

The above are some simple introductions to the car axles. If you have any questions about our products, you can call for consultation. If you have any need for our products, you can come to our company for a field visit.]]>

Broken axle: Symptoms: Wheels may fall off during high-speed driving. Wheel out-of-round will cause inaccurate dynamic balance, which manifests as high-speed steering wheel shake.

The half shaft, also called the drive shaft, is the shaft that connects the differential and the drive wheels. The half shaft is a shaft that transmits torque between the transmission reducer and the drive wheel. A universal joint at each of the inner and outer ends is connected to the reducer gear and the hub bearing inner ring through a spline on the universal joint.

Under the action of long-term torsional fatigue and impact forces, automobile half shafts are prone to bending, twisting and breaking, and spline teeth wear or skew, and other enemy obstacles. For semi-axial fractures, there are several types of morphology:

(1) The semi-axle blue disk falls off or cracks

(2) Fracture of shaft shaft

(3) Helical fracture of axle shaft

(4) Mixed fractures and cracks on the axle shaft

(5) Fracture at half-axis spline

(6) Fractures and cracks of other morphologies of the semi-axis

]]>

Abstract: Through hardness measurement and metallographic examination, it is confirmed that the cause of fatigue fracture of the rear axle half-axis of the automobile is caused by improper heat treatment, which causes more ferrite to appear in the structure of the half-axis, resulting in insufficient hardness and strength.

Chemical composition analysis and hardness determination

1. Chemical composition analysis (GB3077-881).

2. Hardness determination 40CrZB / T21004-89 "Technical conditions of automobile axles", the shaft hardness of the shaft is 24 ^ 30HRC after pre-quenching and quenching, and the surface hardness of the shaft is 52HRC. As a result of actual inspection, the hardness of the semi-axis is relatively low.

Macro and micro inspection

1. Macro inspection The fracture is generated at the spline, the fracture is chrysanthemum-shaped, the entire cross section is inverted cone, and the crack is first generated outside the spline shaft. The heart region, which is grayish black and has no metallic luster, is the final transient fracture region.

2 crack analysis

(1) There are few inclusions in the fractured semi-axle matrix, and there are no inclusions on both sides of the near crack, but there are oxide scales inside the crack, so it does not have the characteristics of cracks caused by non-metallic inclusions;

(2) There is no decarburization on both sides of the crack, its lines are smooth, its tail is slender, and it is not round and bald, excluding non-quenching cracks caused by defects in the raw material itself (white spots, looseness, peeling, and subcutaneous bubbles);

(3) The crack depth exceeds the hardened layer, and the microstructure of the sorbite and bainite in the hardened layer is small and uniform, excluding quenching cracks caused by improper quenching such as high quenching temperature.

3 microstructure

According to relevant literature, the unhardened layer of the 40Cr steel after quenching and tempering is bainite and sorbite, and ferrite is allowed in the heart.

Samples were taken at the spline shaft rupture and observed under an optical microscope. The spline tooth structure was tempered sorbite and tempered bainite. The matrix structure of the semi-axial part is sorbite, and there are reticular and needle-shaped ferrites distributed along the grain boundaries, and the black agglomerates are bainite. It can be seen that the ferrite content gradually increases with the distance from the bottom of the spline to the heart.

4 discussions

According to the composition analysis, it can be known that the chemical composition of the material used in the semi-axis meets the composition requirements of 40Cr in the standard GB3077-88, and the steel is pure, so the factor of fracture due to misuse of materials and poor steel can be ruled out.

The hardness test results at the half-axis splines show that the hardness values ‚Äã‚Äãfrom the core to the teeth are significantly lower. Because the working environment of the half shaft is harsh, and it is subjected to two-way alternating torsional stress, and the spline shaft is a force fulcrum, insufficient hardness may cause a fatigue core to form at the angle of each groove, and at the same time The two 45 ìÔ lateral extensions meet at the center of the shaft and form a star-shaped fracture.

From the microstructure point of view, the semi-axis contains more ferrite and precipitates in a network and needle shape along the grain boundaries. Generally, the automobile axle shaft needs to be quenched and tempered, that is, the axle shaft is heated to Ac3 + (30 ÔΩ?50 ‚Ñ?, held for a period of time, and then cooled at a rate greater than the critical cooling rate, and the austenite is supercooled without touching the nose of the C curve. All transformed into martensite. If the cooling rate is lower than the critical cooling rate, a part of austenite will transform to bainite and bainite, and ferrite will preferentially precipitate along the grain boundary, causing the hardness and strength of the steel to decrease. There are generally two reasons for this: one is the improper selection of cooling medium; the other is due to mass production, too many furnaces installed, poor thermal and thermal cycles caused by the accumulation of parts, making the C curve to the left, and bound to be hardened after quenching The appearance of bainite and undissolved ferrite. Undissolved ferrite in this quenched structure cannot be removed by high temperature tempering. The purpose of tempering is mainly to eliminate the internal stress caused by quenching and lattice distortion, reduce hardness, improve plasticity and toughness, and there will be no change to the existing ferrite. The fine reticular ferrite that appears in this semi-axial microstructure is also the structure that exists after quenching. The difference is that the bulk ferrite is caused by the low quenching temperature and insufficient holding time, and is not fully austenitized, while the network ferrite is due to the slower cooling rate during the cooling process, and the ferrite is preferential along the grain boundaries The reason for precipitation.

In the requirements of quenched and tempered steel, more free ferrite is not allowed to exist in the tempering structure, especially the fine mesh free ferrite distributed along the grain boundary. Not only does it reduce strength, it also directly affects fatigue fracture. Because the damage of steel parts always starts with low strength free ferrite, especially steel parts working under complex alternating stress. Once free ferrite is in the heart, ferrite is under cold working during work. In the hardened state, with the extension of working time, it will develop from hardening to brittleness to a certain limit, and then brittle fracture. In addition, due to the difference in strength and plastic deformation between ferrite and sorbite, steel parts undergo different plastic deformation when they are subjected to the same stress, which causes greater stress in the grain boundary part in two adjacent components. And deformation, this kind of residual stress and deformation will cause grain boundary fracture once it exceeds the crack strength of steel, and when it continues to expand, it will become the main source of fatigue fracture. Therefore, the presence of more ferrite in the semi-axial structure is the root cause of fracture.

]]>

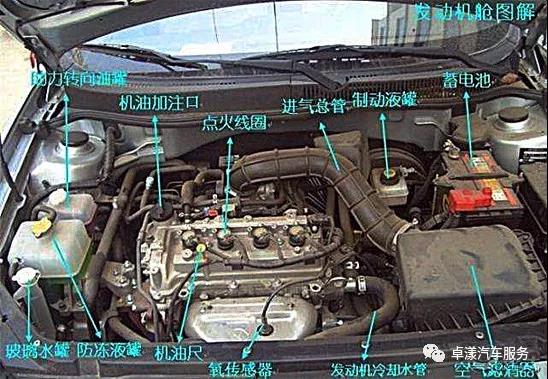

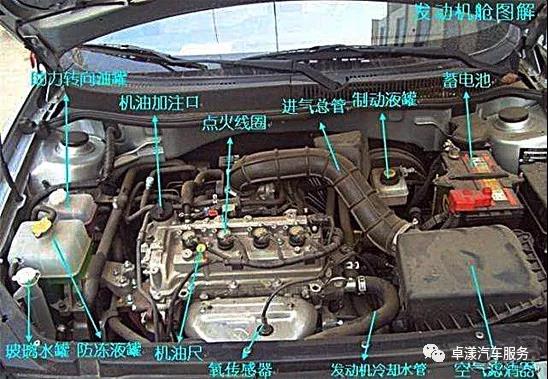

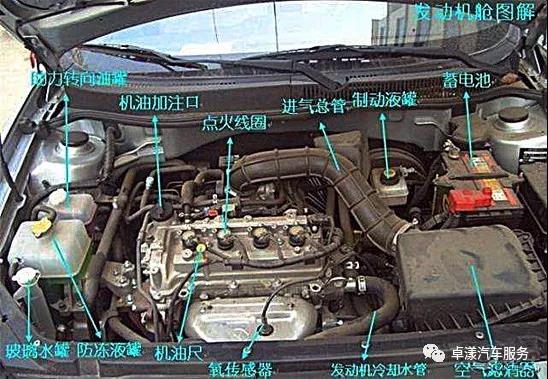

Air filter: Its role is to filter the dust and impurities in the air and let the clean air enter the engine, which is very important for the life and normal work of the engine. The dust and dirt absorbed by the air filter will be blocked and affect the engine operation, so it must be replaced regularly. If you drive in a dusty place, such as a sandstorm, the air filter replacement cycle will be shortened.

Battery: Needless to say, it is used to store electrical energy. Usually lead-acid batteries, the electrolyte is dilute sulfuric acid.

Brake fluid: Brake fluid as usual. At present, the brakes of cars are generally hydraulic, that is, the brake fluid is used as the medium to transfer the force of the brake pedal to the brake disc.

Ignition coil: The low voltage is converted to high voltage, and the spark plug discharges below it to generate electric sparks, which ignite the oil-gas mixture to perform work.

Motor oil: Needless to say, mineral oil or synthetic oil that acts as a lubricating seal. If the engine lacks the lubrication of the oil, it will cause serious problems such as pulling cylinders and holding shoes.

Power-assisted steering oil: Nowadays, the steering assistance of a car is usually the traditional hydraulic assistance. Since it is hydraulic, the oil medium is needed.

Antifreeze: Circulate in the channel of the radiator and the engine cylinder. The liquid medium used to cool the engine, mainly water and additives, is called antifreeze because of its antifreeze function.

Glass water: Everyone on the planet knows that it is used to clean glass. Now you should know where it is.

Oil dipstick: a ruler that detects the amount of oil. When using the engine, turn off the engine first, pull out the oil dipstick, wipe the oil on it with a clean paper towel, and then insert and pull out again. The oil level of the oil must be between the two upper and lower limits on the ruler. Can't be less.

Fuse box: There are many fuses for electrical equipment, and relays. There are two safety boxes in the small F, and the other one is on the lower left of the cab driver. See the accompanying manual for details.

Air inlet: The inlet of the engine's air intake. This is optimized. The position has been improved a lot. The air inlet of the old car is relatively low, and it is easy for the engine to enter water when wading. The position of the air inlet is the limit of the wading depth of the car, and it must not be exceeded. Once the engine enters the water, the consequences are very serious ~!

Electronic throttle: It is said to be an accelerator. Actually, it has nothing to do with oil. It is connected to the intake manifold and the intake manifold, and controls the engine air intake, so the correct term should be the electronic throttle. The engine control module calculates the fuel injection amount based on the intake air volume, so that the engine speed and output power can be controlled.

Intake manifold: the branch branch from the intake manifold to each cylinder. Although it's a tube, it has high-tech content, such as a variable intake manifold.

Carbon canister valve: The carbon canister absorbs the gasoline vapor in the fuel tank. After the carbon canister valve is opened, the engine will suck the gasoline vapor adsorbed by the activated carbon in the carbon canister into the intake pipe, and finally participate in the combustion. This is good for environmental protection and saves a little oil.

Gasoline Distributor: Distributes gasoline to each fuel injector. The fuel injector is connected underneath it, which is blocked from view.

Crankcase ventilation pipe: the right side is the intake pipe, and the left side is the exhaust pipe, which is used to ventilate the crankcase.

Injector: The gasoline pressurized by the gasoline pump is sprayed out in an atomized form. The nozzle hole is very small, so that the gasoline can be atomized better, but it is also easy to be blocked, so the nozzle should be cleaned regularly.

Vacuum booster: Using the force generated by the vacuum negative pressure of the engine intake pipe and the pressure difference between atmospheric pressure to assist the brakes, it can reduce the driver's "labor intensity".

Brake master cylinder: Generates brake fluid pressure, which is transmitted to each brake cylinder through the brake oil pipe.

Clutch master cylinder: When the clutch pedal is depressed, the clutch master cylinder connected to the pedal will act, generate hydraulic pressure, and transfer it to the clutch pump along the pipeline, and finally convert it into a mechanical force release clutch. The small F's clutch operating system is hydraulic and shares a hydraulic fluid with the brake system, so a tube is connected to the brake fluid tank.

ABS pump: a very important safety device ~! ABS means automatic anti-lock braking system. When the brake is applied, the ABS system will automatically apply a few dozen times per second to the wheels according to the speed and braking force. To prevent tires from slipping and getting out of control. And it can provide steering ability to avoid obstacles when braking.

Power Steering Pump: Provides hydraulic power for steering assistance. The problem of abnormal sound of the belt is the displacement of the booster pump bracket, which causes the pulley of the booster pump to be not on the same plane as the other pulleys. When the belt runs, the friction with the pulleys causes abnormal noise and noise.

Air-conditioning compressor: Compresses the vaporized refrigerant into a liquid, and then pumps it into the evaporator to produce the coolness we need ~!

Exhaust manifold: The exhaust gas generated by each cylinder of the engine is discharged into the exhaust manifold through the exhaust manifold, and then discharged into the atmosphere through the three-way catalyst and muffler. Because the exhaust gas of the engine is very hot, a protective shell is added here to play the role of heat insulation. Seeing that hand-shaped logo is not there, there is also an X, which means don't touch it, it will burn you ~!

Oxygen sensor: Detects the oxygen content in the exhaust gas and sends a signal to the engine control module, which is used to control the fuel injection amount so that the fuel can be fully burned and reduce emissions. If there is a problem with the oxygen sensor, the engine is said to be unstable at idle and fuel consumption will increase dramatically.

Clutch pump: The clutch of the small F is hydraulically driven. The clutch master cylinder generates hydraulic pressure, which is transmitted to the clutch pump along the clutch oil pipe to generate mechanical force. It pushes the release lever on the right to disconnect the clutch. The hydraulic zip cable is much easier to use.

Selecting and shifting cable: One end of the cable is connected to the gear lever in the cab, and the other end is connected to the gear selection and shifting mechanism. The cable has a great impact on the feeling of shifting. If you have difficulty in gear shifting, it may be a problem with the cable ~!

Starter: In fact, it is a small motor. When the key switch is turned to the start position, the starter rotates, and at the same time, it drives the engine to assist the engine to start working. If it is difficult to start a fire when starting the car, the duration of the fire cannot be too long, a few seconds at a time. It has been unsuccessful for several times in a row. You should screw the key back, wait for a few minutes, and allow the starter to cool down before powering on again. This prevents the starter from burning out.

Let's take a look at the gasoline pump again. After the rear seat is opened, you will see such a black cover. Below it is the gasoline pump.

After removing the cover, you can see the gasoline pump. It is actually installed on the fuel tank, but it is troublesome to remove the fuel tank, so a hole is opened in this place, which can be easily replaced when the gasoline pump is damaged.

The gasoline pump is dismantled, and it looks like this! Since it is called an oil pump, its role is needless to say that it is a pump of oil. The gasoline pump pressurizes the gasoline and sends it to the fuel injection nozzle from the fuel supply pipe. Because of the pressure, the gasoline sprayed from the fuel injection nozzle will be atomized well and can be evenly mixed with the air.

There is a very important note in the use of gasoline pumps, which is to keep the fuel in the fuel tank too low. Do not wait until the oil lamp is on before refueling. If you see it, add it, because the gasoline pump depends on the gasoline in the fuel tank to cool it.

Gasoline filter: Installed in front of the right rear wheel, next to the fuel tank, it is used to filter out moisture, impurities and gums in gasoline, prevent fuel system blockage, and ensure the normal operation of the fuel supply device.

Brake hose: transmits the force of the brake pedal.

Brake cylinder: The hydraulic pressure of the brake fluid is converted into mechanical force, which acts on the brake caliper. The friction plate on the caliper produces friction with the brake disc, which converts the car's kinetic energy into heat energy and consumes it, thereby stopping the car.

Stabilizer: Reduces vehicle roll when steering and increases handling.

Half shaft: transmits the power of the engine to the wheels to drive the car.

Steering lever: Control the steering of the wheels and adjust the toe.

Lower arm, upper support arm: Suspension member connecting the wheel and the body.

Cardan shaft: connected between two shafts, the transmission angle between the two shafts can be arbitrarily changed within a certain range. Because the front wheels are driven and steered ~!

Spring: elastic element, which acts as a buffer. This is a coil spring. Trucks use leaf springs. Some high-end vehicles use air springs.

Shock absorber: a hydraulic damping element that absorbs the energy of the road impact and suppresses the force of spring back after compression. It cooperates with springs to form a shock absorption system, which is used to reduce vehicle body vibration caused by uneven road surfaces. The damping force of the shock absorber and the spring force of the spring, through different tuning and matching, will produce different chassis styles, such as sporty and comfortable.

Handbrake cable: When the handbrake is pulled, the rear wheel is braked, just like a bicycle brake.

Exhaust pipe soft connection: Block the transmission of engine vibration.

Sub-frame: Suspension member connecting the hem arm and the body.

Three-way catalytic converter: converts NOx, CO and other harmful gases in the exhaust gas into harmless gases such as N2 and CO2, reducing emissions and pollution.

Muffler: Eliminates noise from engine exhaust. Without this thing, our cars would be as loud as sports cars.

Activated carbon canister: A small black canister installed on the right side of the rear of the car. The interior is filled with activated carbon and connected to the fuel tank, which is used to absorb gasoline vapor. When the car starts, the activated carbon canister solenoid valve is opened in time to pour the absorbed fuel vapor back into the intake manifold to achieve fuel saving and environmental protection.

Torsion beam: A torsion beam type semi-independent suspension member can produce a certain torsional deformation, which makes the suspension performance between independent suspension and non-independent suspension. The characteristics of this suspension are low cost, high strength, small footprint, and average comfort, which are mostly used on small cars.

]]>

Chews know that car jitter is one of the most common problems in cars. Some people think it is a small problem, but often there are big problems behind this "small problem". If you do not eliminate the problem in time, it is likely to cause a bigger hidden danger.

First of all, we need to distinguish whether the body is shaking or the engine is shaking: if the car is shaking from the start of ignition, it can basically be determined that the engine is shaking; if the car starts to shake after starting, it can be determined that the body is shaking.

Body shake

Brake disc is not flat

The poor driving habits of the owner, such as frequent braking and sudden braking, may cause problems such as uneven deformation of the brake disc. It doesn't feel like driving when you are driving, but when you step on the brakes, it will be accompanied by body shake and brakes.

Tire problem

The vehicle has slight jitter or some swing during the driving process. It may be that the tire is deformed or the cause of the imbalance. Check the tires as soon as possible and make a four-wheel balance.

Steering mechanism failure

Problems with the steering mechanism can also cause car shake, especially in cars with hydraulic transmission systems. If the steering power is lost, and the steering device fails, the car is likely to be shaken while driving.

Drive the half shaft differently

The car axle is the final drive for the power transmission of the car engine, which causes the drive wheels to rotate and push the car forward or backward. If the half shaft is deformed or bent, it will cause the car to shake. This kind of situation is generally manifested in the case of the car idling without problems, it will shake when it is opened, and it will be no problem when it returns to idle speed again.

Body shake

Lack of fire

If there is a problem with the ignition coil or if the spark plug cannot jump for some reason, the combustion efficiency of the engine will be reduced and the car will be shaken. If the car is much more dither than usual when running at low and medium speeds, and there is a sense of powerlessness during acceleration, it can be basically determined that the engine is out of cylinder.

Too much carbon

After the car has traveled for a certain mileage, the throttle may be too tight due to excessive dirt or the idle stepping motor may be stuck, which may cause the engine to idle too high. The carbon deposits generated by the engine during operation can also cause vehicle shake. If the car's acceleration ability is not as good as before, and the jitter is very long, then you can consider the engine cylinder cleaning.

Engine mat mat aging

This is often the case with older cars. The engine's base pad is actually a suspension system for the engine, which is responsible for filtering some of the slight jitter generated by the engine at high speeds. When the mat is aged, the vibration of the engine is transmitted to the entire body. If your car's engine is getting more and more jittery, but the power is not getting weaker, you can consider whether it is a problem with the engine floor mat.

Circuit problem

There are many sensor devices on the engine that transmit engine signals, such as crankshaft sensors, knock sensors, and more. If there is a problem with these sensors, the engine intake and fuel injection may be adversely affected. These problems may affect the engine ignition and engine shake.

Axle casing installation Rolling journal and bearing journal wear, leading to its axis, with Songkuang between the hole, the bearing inner race in the journal slide turn cause friction surface wear and tear. Bearing inner race in the journal slip severe, will produce high temperature, the journal annealing reduced strength of the material damage. Axle casing seamless steel pipe is made, after bending, grazing between the axle and the sleeve both abnormal sound, and even affect the normal meshing planetary gear, accelerated wear, leading to tread swing.

Axle tube stop on the axle housing or casing screw threaded bore hole wear, after the stopper screw cut, resulting in the sleeve and can not stop moving, this will cause wheel Yi threaded shaft head wear, the bearing axial moving wheels swing in operation, an increase of driving resistance, affect the braking performance, the tire malignant abrasion, severe under excessive axial force, will have a "flywheel" accident.

]]>

We know that the power output of the engine does not directly act on the wheels to drive the car, but the force is transmitted through the drive shaft. The transmission shaft is the shaft that can transmit power in the transmission shaft of the universal transmission. It is an important component of the transmission power in the vehicle transmission system. Its function is to transmit the power of the engine to the wheels together with the gearbox and the drive axle, so that the transmission of the vehicle Driving force. It is a high-rotation, low-supporting rotating body, so it must be balanced at high speed. Generally, the drive shaft must be tested for dynamic balance before leaving the factory and adjusted on the balancer. For the front engine rear-wheel drive vehicle, the rotation of the transmission is transmitted to the shaft of the final drive. The transmission shaft can be two or several sections, and the joints can be connected by a universal joint.

In general, the connection between the gearbox and the differential is called the drive shaft. The drive axle is called the half shaft and is divided into the front half shaft and the rear half shaft. Generally speaking, if the gearbox and the differential are integrated, there is only a half shaft. Mostly for the front drive. If the gearbox and the differential are separated, then there is a drive shaft.

There are several drive shafts in a car that are related to the drive mode:

The front drive generally has two half shafts, called the front left and right axles;

Rear-drive, generally two rear axles and one drive shaft are connected to the gearbox and the rear differential;

4WD, generally having two front axles, two rear axles, a rear drive shaft between the gearbox and the rear differential, a front drive shaft between the gearbox and the front differential, and a shifting A small drive shaft between the box and the transfer case.

Why are the drive shafts of the car hollow and the half shafts solid?

The shaft tube of the main drive shaft is hollow, because the drive shaft drive shaft only needs to withstand the torsional stress, that is to say, the deformation on the drive shaft is only distorted, so to tell you, the cross section of the drive shaft is a circle, when the shaft is twisted When the force is strong, the distance from the center of the circle is the greatest. The closer to the center of the circle, the stress is actually very small, and the force received at the center of the circle is 0. Therefore, the center of the circle is hollowed out and there is no axis. What impact, but for the manufacturer, it can save a lot of materials, it needs to be emphasized that this is not a cut-off, which is a very reasonable promotion.

However, in addition to torsional stress, the half shaft needs to withstand shear stress and bending stress. The force of the half bearing is much larger and more complicated. In order to meet the requirements of strength and rigidity, the half shaft is solid.

We all know that the car axle is a product used in our car. Its use is very good. So what do we need to do in the actual work for its performance? Next, Xiaobian will take us all to learn more about product knowledge.

It is very important for the application of various types of auto parts in our cars. The semi-axle of the car is a product used in the car. It is a solid shaft. They are processed by standardization and the use of the product. Very stable, if you operate in the correct way during the process, they will not easily break or twist. Some of the indicators and lines that this product can withstand have passed. Test, the performance is no problem. Once the product has some distortions, etc., generally can not be repaired, only a direct replacement. This product also has some drawbacks in the market. Because many small In order to be able to achieve a certain profit, some of the materials used in the process of production will cut corners, and the tolerance of the products will be affected to some extent. In the process of rapid driving, they are very vulnerable to some hard objects. Cause damage.

The above content is our introduction to the knowledge about the axles of the car. I believe we all have more understanding of the products. If you are interested in our products, you can call our hotline at any time. We look forward to working with you for a long time.

ÂèëÈÄÅÂèçȶ?br />ÂéÜÂè≤ËÆ∞ÂΩï

Summer car maintenance knowledge

1, tire pressure

The tire must be inspected and replaced with a new one if the pattern is worn out. The air pressure in the tires in summer will increase with the increase of temperature, and often cause a puncture accident. At the same time, the speeding, overloading or emergency braking of the vehicle is easy to cause the puncture. Therefore, it is possible to appropriately reduce the tire air pressure, or to change the tire to a helium gas whose physical properties are more stable and difficult to expand.

2, the use of air conditioning

First open the air conditioning outside the cycle. In summer, the temperature inside the car is often very high. Therefore, do not turn on the air conditioner immediately when the car starts. You should open all the windows for 3-5 minutes, then turn on the air conditioner after the hot air is exhausted, which will have a better effect. If the engine is under heavy load for a long time, the air conditioner should be turned off temporarily. When cooling, the wind direction of the air conditioner is best to blow upwards, because the cold air will sink downwards, and it is best to select the blowing surface block for the wind direction gear. Finally, notice that the air conditioner is turned off before the destination to reduce the occurrence of odor.

3, body care

There are more rains in summer and autumn, rainy acid in rain, strong sunlight, and gum falling on the surface of the car will cause corrosion and oxidation of the paint surface. After a long period of rain and sun exposure, the face of your car must be tormented and unbearable. Therefore, it is necessary to make a series of beauty care from the cleaning, polishing, waxing, sealing glaze to the body. Even if your body has been painted, it is time to take care of the body and wash it off.

4, compressor and condenser

After deactivating the refrigeration system, the compressor should be operated for more than 10 minutes every two weeks; the belt tension of the compressor should be checked regularly; if the refrigerant oil leak is found, it should be disposed of in time; the condenser should be cleaned frequently to prevent oil, dirt and debris. Attached to the heat sink of the condenser.

5, wiper blade

Due to the large amount of rain in summer, the frequency of use of automobile wiper blades is very high, so it is especially important to strengthen the inspection of wiper blades. In addition to regular inspections, it is also necessary to pay attention to the cleaning of the wiper to prevent the wiper from accumulating dust and impurities, which may affect the wiping effect, or adversely affect the front windshield of the car. Once the working effect of the wiper blade is not ideal, it is necessary to repair and replace it in time, and do not lose it because of smallness.

6, sterilization in the car

It is important to do a good job of car disinfection during spring and summer. Ventilation should be done frequently to clean the exterior and interior of the car regularly. When cleaning, you can use your own disinfectant to scrub. If you have time, you can also use a UV lamp or high temperature sterilization at a special maintenance shop. However, it must be noted that the disinfection of the air in the cabin is carried out in the absence of the vehicle. After the disinfection is completed, it is necessary to open the window for 5 to 6 minutes, wipe the facilities in the compartment with water, and then dry with a clean cotton cloth to remove the residual disinfectant.

Summer car maintenance precautions

1, the battery is deficient

In summer, the temperature is high, the water in the battery electrolyte evaporates quickly, the liquid level drops rapidly, and even the electrode plate is exposed to the liquid surface, causing the battery to lose water and early damage. Therefore, in summer, the liquid level in the battery should be checked frequently, and distilled water should be added in time to ensure the normal liquid level and ensure that the battery is in good working condition.

2, the engine body is overheated

In summer, the ambient temperature is high and the engine is prone to overheating. Therefore, in the summer, the inspection and maintenance of the engine cooling system should be strengthened, including the water tank, thermostat, water pump, fan, etc., and the cooling water should be added in time. When the water temperature exceeds 100 ìÔC, stop in the shade to cool down, let the engine idle, and open the hood to facilitate heat dissipation. Can not put antifreeze, antifreeze is generally changed in two years!

3, anti-lubrication

When the temperature is high, the viscosity of the oil is lowered, and the oxidation resistance is deteriorated, resulting in poor lubrication. Therefore, in the summer, the oil quantity should be checked frequently and added or replaced in time; the oil filter and radiator should be cleaned in time to ensure smooth oil flow and good heat dissipation, and try to avoid overloading the engine.

4, anti-engine deflagration

In summer, the temperature is high, and the daily maximum temperature is often above 35 ìÔC. The failure rate of the car itself is greatly improved, and natural deflagration is prone to occur.

5, anti-brake failure

Brake fluid evaporates and vaporizes in a high temperature environment, forming a gas barrier in the brake pipe, and the brake shoe is also easily ablated, causing brake failure. Therefore, in the summer, the brake system should be checked and adjusted in time. On the way of the long slope, the parking brake should be paid to ensure good braking performance. If the brake hub is found to be hot, stop the cooling, but do not pour cold water to prevent the brake hub from rupturing. .

6, the anti-car paint is damaged

Although it does not seem to have life, it is also afraid of the sun, long-term exposure will be old, wrinkled. Ordinary beauty waxing, although some functions, but because any car wax contains bismuth ingredients, after long-term exposure to ultraviolet light will rust paint, leaving a little black spots. Moreover, the car wax itself does not function to enhance hardness and resist ultraviolet rays, and will quickly lose due to excessive temperature. Therefore, the car should be parked in a cool place when parking.

Summer maintenance car precautions

1. Volatile fast antifreeze is essential

In summer, the coolant evaporates quickly. Always check whether the coolant is missing. If it is missing, replenish the same brand of antifreeze in time. Do not add other brands of antifreeze or water. Because antifreeze is the main working medium in the automotive engine cooling system, its main function is to make the engine cooling system through the forced circulation to keep the engine at the proper working temperature.

2, protect the car paint parking in the shade

Although it does not seem to have life, it is also afraid of the sun, long-term exposure will be old, wrinkled. Ordinary beauty waxing, although some functions, but because any car wax contains bismuth ingredients, after long-term exposure to ultraviolet light will rust paint, leaving a little black spots. Moreover, the car wax itself does not function to enhance hardness and resist ultraviolet rays, and will quickly lose due to excessive temperature. Therefore, the car should be parked in a cool place when parking.

3, the interior is completely disinfected

Due to the hot summer, many car owners do not often drive windows, and often only choose the inner circulation for the wind power of air conditioners. For a long time, the air inside the cabin has become turbid, especially in the hot and humid weather before the thunderstorm, bacteria are also easy to breed. At this time, the owner can choose to buy some interior cleaners or go to the car beauty shop to thoroughly clean the car interior.

4, air conditioning is best to clean

Many car owners often do not make big moves when the vehicle is used without problems. Among them, for example, air conditioners, owners who do not clean all year round are not uncommon. However, in summer, the air conditioner in the car will be used for a long time, and it is necessary to do a thorough cleaning. In addition to the removal of odors, a large amount of dust, dirt and bacteria that are inhaled by the air inlet of the air conditioner are likely to affect human health.

The car half shaft is the two connected solid shafts. The role in the car is very important, especially in the process of turning the car, the arc can be controlled, the speed of the left and right wheels plays a very important role in the normal driving of the car, and at the same time in the process of use. Among them, they can also make up for the difference in price based on the speed. In order to make their performance more stable, in fact, there will be a layer of dust jacket on the surface. If the dust jacket is damaged during use, it must be replaced in time. If it is not replaced in time, the cage is very It is easy to enter the water, and the cage is also very afraid of entering the water. If there is water ingress or into the group, the internal wear of the shaft dragon will increase, and even affect their application. Therefore, in order to ensure their application, regular maintenance and overhaul must be done.]]>

Under the action of long-term torsional fatigue and impact force, the axle of the automobile is prone to failures such as bending, twisting and breaking, and spline tooth wear or skew. The most common faults in automotive axles are as follows:

First, the bending of the half shaft, at this time the owner can put the half shaft on the V-shaped iron or on the lathe, check the neck of the oil seal with a dial gauge, the pointer should not exceed 5mm, otherwise it should be cold-pressed and straightened. .

Second, the half shaft flange plane should be perpendicular to the center line of the half shaft. In the case where the semi-axis has no q-curve deformation, the basin is measured at the edge of the flange with a dry minute meter, and the pointer yaw cannot be larger than 0.2 mm, otherwise it should be corrected by buffing.

Third, the half shaft spline tooth and the gear spline groove matching clearance can not be greater than 0.75mm, the half shaft spline tooth skew should not be greater than 1.00mm, otherwise it should be replaced with new parts or surfacing repair.

Fourth, the wear of the half shaft oil seal neck can not be greater than 0.3mm, otherwise surfacing or chrome repair.

5. If the half shaft breaks or has cracks, it should be replaced with new ones.]]>

The axle of the car is connected to two wheels. It is very simple to look at the product in appearance, but their role is very important. They must protect the torque of the wheel under different conditions and also bear the gravity of the car itself. . In the past, some data showed that they would not easily bend or break under normal circumstances. If the damage could not be repaired, only the direct replacement could directly affect the use of the factors due to improper operation or It is caused by overloaded driving. The weight of the car body plus the weight of the cargo will directly reach his tolerance limit, which will easily cause damage. In addition, it is very uniform in the process of use, afraid of water or dust. Therefore, we must pay attention to the protective dust cover of the semi-axle. If it is found that the protective dust cover has been damaged, it should be replaced in time to avoid directly affecting the use of the semi-axle.

]]>

Correct handling of shaft oil seal oil leakage! Half shaft oil seal leakage This is a situation that we often encounter when we use a car. For a novice driver who does not know the car, if it is a half shaft oil seal, it is quite annoying. It is totally unclear how to deal with it. Today, Xiaobian will tell you the reason and correct treatment of the oil leakage of the semi-axle oil seal.

Half shaft oil seal leakage reason

Many friends know that the semi-axle oil seal is very harmful, which may lead to a decrease in the amount of lubricant in the drive axle, which will affect the normal lubrication and increase the wear and tear of the machine parts. It will cause damage to the brake drum, causing poor braking and endangering safe driving. Or the lubricating oil flows into the wheel reducer, causing the oil level of the wheel reducer to rise and damaging the oil seal. Therefore, the oil leakage of the half shaft oil seal can not be ignored. Let us look at the cause of the oil leakage of the half shaft oil seal.

1. There is too much oil in the drive axle reducer, and the oil level exceeds the normal height.

2. The sealing effect caused by the aging of the oil seal is degraded.

3. There is a problem with the installation of the oil seal, there is a gap.

4. The drive axle reducer vent is blocked. When driving, the oil temperature rises, the pressure rises, and the oil is squeezed out, causing damage to the oil seal.

5. The quality of the semi-axle oil seal is not good, the size does not match, and the oil seal and the semi-axle sleeve are too loose.

6. The hub bearing is loose, the reducer bearing is loose, and the half shaft is shaken up and down.

7. The seal caused by the wear of the semi-axle journal is not strict.

Semi-shaft oil seal leakage solution

1. Whenever you change the oil, it must be the same as the oil level.

2. Remove the reducer vent cleaning for each maintenance.

3. Choose a suitable and quality half shaft oil seal.

4. The main oil seal is installed correctly when installing the oil seal.

5. For oil seals that may age, they need to be replaced in time.

6. Check the tightness of the hub bearing during secondary maintenance, and make sure that it is not loose.

The axle of the car is the drive shaft. When the car is turning, the left and right wheels have different trajectory radii, so the distance traveled during the turn is different. The outer wheel has to travel a long distance. If the power is transmitted to the same size wheel through a complete shaft, the two wheels The same speed, the same diameter and the difference between the two wheels when turning, it is necessary to make the wheels on the inside of the curve slip and idling (not walking), which makes the turning difficult; to overcome and improve the problem, the vehicle drive shaft is divided into The two halves are separated by left and right, and the middle is connected by "differential". When the vehicle is running straight, the two wheels can get the same driving force. When turning, the inner wheel rotates at a lower speed than the outer wheel due to the differential. In this way, it is achieved that the two wheels simultaneously drive the vehicle forward but the outer wheels move more than the inner side. The use of two half shafts on the drive shaft is designed to improve the cornering performance of the vehicle.]]>

With the rapid development of China's automobile industry, the demand for automobile axles is increasing. How to improve the output and quality of automobile axles, reduce the production cost of axles, realize economic production of semi-axles, and meet the needs of the market has become Important issues that need to be addressed urgently. Therefore, it is of great practical significance to explore the method and technology of automobile semi-axis precision forming. The car axle is an important force transmission component of the car. It not only transmits the torque from the car engine, but also the vertical force acting on the wheel, the lateral force and the longitudinal force formed by the traction and braking forces. Therefore, the car axle is an important part of the automotive transmission system.

]]>

The rear axle half shaft is also called the transaxle.

The rear axle half shaft is a solid shaft that transmits torque between the differential and the drive wheel, and the inner end is generally connected to the rear axle side gear through a spline, and the outer end is connected to the hub. Depending on the type of support, there are two types, full float and semi-floating.

The full-floating rear axle half shaft transmits torque only and does not bear any reaction forces and bending moments, so it is widely used in various types of vehicles. Easy to disassemble, just pull out the bolts on the flange to pull out, and the wheel and axle housing can still support the car, which brings convenience to the car maintenance.

The semi-floating rear axle half shaft transmits both torque and full reaction and bending moments. Its support structure is simple and low in cost, so it is widely used in various types of cars with small reaction bending moments. However, such a rear axle half shaft support is troublesome to be removed, and if the rear axle half shaft is broken during driving, the risk of the wheels flying off is easily caused.

Our company is a professional production base for light trucks, medium trucks and heavy trucks. It produces 500,000 pieces of semi-axle production capacity annually. Physicochemical analysis, magnetic flaw detection, metallographic microscope, yaw detector and other quality testing methods, advanced YTD41-200 preloading press, DTW99-200 pendulum milling machine, RT2-150 resistance furnace, GCL-1205 induction hardening Machine tools, YB60502G high-speed flower milling machine, Y631K flower shaft washing machine, CNC machine tools processing complete production equipment.

]]>

Axle differential is torque transmission between the solid shaft and the drive wheels, the inner end typically by a splined connection with the side gears, the outer end of the hub is connected.Axle differential is torque transmission between the solid shaft and the drive wheels, the inner end typically by a splined connection with the side gears, the outer end of the hub is connected.

Hyundai common axle, according to their support in different forms, there are full floating and semi-floating two.

Full floating axle torque transfer only, does not bear any reaction forces and moments, which are widely used in various types of vehicles. Full floating axle easy disassembly, simply unscrew the bolt on half axons margin can be withdrawn axle, and wheel and axle can still support cars, making it easy to bring the car maintenance.

Both semi-floating axle transmission torque and withstand the full reaction force and moments. It's simple support structure, low cost, which is widely used on small reaction force moment all types of cars. But this axle support cannibalize trouble, and cars with the broken axle if danger is easy to fly off the wheel.

June's heavy truck market is still stagnant in the trough. Despite the narrowing its monthly decline, but the decline is still very alarming, abnormal sluggish end-market demand has not changed so far.

June 47 000 heavy truck sales fell 26%.

The latest was informed that in June the domestic heavy truck market a total of about 47,000 sales of all types of vehicles, down 26 percent from 63,720 last year, the chain in May this year (51 712) also fell by 9%. Among them, Dongfeng, heavy truck were sales of heavy trucks 10,400, and 8800, year on year decline of 24% and 4%; FAW heavy truck sales of 6,100, down 34%; Shaanxi Auto and Foton sold cars 7500 and 6400, respectively, an fell 26% and 30%. The third camp, Jianghuai heavy truck sales of 1,800, down 57%; Valin star horse, big marketing cars 1238 and 1365, down 19% and 15%; North Pennines and SAIC Iveco Hongyan heavy truck sales in June were 1000 (an increase of 7%) and 880 (down 45%).

June and the first half of the heavy truck market remains in the doldrums, the reason has been analyzed many times, here I also do not want to repeat too much. The fundamental reason, in fact, the macroeconomic slowdown and fixed asset investments (infrastructure and real estate, etc.) sluggish investment. hile May and June investment in infrastructure projects has been approved by the State nominally several rounds (according to statistics, as of July 1 Development and Reform Commission approved a total of 35 large-scale infrastructure projects, including railways, urban rail transit, airport construction, the scale of investment 819.62 billion yuan), but substantial start, at least until the mid-third quarter; and the manufacturing recession (June manufacturing PMI purchasing managers index was 50.2%, unchanged from last month only to maintain, the production side of the weak and demand end of the downturn, the domestic manufacturing sector to stabilize weak foundation is not solid), resulting in falling freight rates, many places are already record low, a large number of transport vehicles in the outage or semi-shutdown state.

Or the rapid decline in the third quarter narrowed Overall, since January this year since the monthly double-digit sales decline (in January fell 22%, down 50 percent in February, down 30 percent in March, April down 33 percent, down 30 percent in May, down 26% in June), therefore, the domestic heavy truck market in the first half the cumulative decline has been high. January to June, the heavy truck market totaled 292,200 vehicles sold, down 32%, compared with January-May of 33% of the cumulative decline narrowed slightly (perhaps better than nothing).

Specifically, the wind continues to dominate the industry first, first half sales of heavy trucks 65,600, down 24 percent, lower than the industry overall decline; heavy truck industry ranked second in the first half total sales of 54,200, down 23%, a decline also lower than the industry average. FAW and Shaanxi Automobile cumulative sales roughly equal, at around 41,900, but the decline FAW heavy truck reached 39%, higher than the industry overall decline, Shaanxi Auto decline of 32%, consistent with the decline in industry; on Fukuda heavy truck half sales of 38,600, down 40 percent. n the third camp, JAC total sales of 16,000, up 32% decline; CAMC total sales of 8711, down 26%; the Grand Canal in the first half 7387 sales year on year decline to single digits (-7 %). North Pennines and Red Rock cumulative sales 5262 and 4792 vehicles, down 18% and 69%, respectively. ).

Looking to the second half, due in 2014 7, monthly heavy truck sales relatively low base in August (last July was 50,618, in August to 48,126, unlike the monthly sales in the first half of the year as "High"), and therefore, monthly sales year on year decline in the third quarter of this year is expected to shrink to less than 20%, so that the cumulative decline in the heavy truck market also will be narrowed to less than 25-30%. But really warmed up the market, as well as steady growth in insurance growth to be national policy more aggressively "overweight" and continued afterburner.

]]>

Axle casing installation Rolling journal and bearing journal wear, leading to its axis, with Songkuang between the hole, the bearing inner race in the journal slide turn cause friction surface wear and tear. Bearing inner race in the journal slip severe, will produce high temperature, the journal annealing reduced strength of the material damage. Axle casing seamless steel pipe is made, after bending, grazing between the axle and the sleeve both abnormal sound, and even affect the normal meshing planetary gear, accelerated wear, leading to tread swing.

Axle tube stop on the axle housing or casing screw threaded bore hole wear, after the stopper screw cut, resulting in the sleeve and can not stop moving, this will cause wheel Yi threaded shaft head wear, the bearing axial moving wheels swing in operation, an increase of driving resistance, affect the braking performance, the tire malignant abrasion, severe under excessive axial force, will have a "flywheel" accident.

]]>

When cars turning left and right sides of the wheel due to the different trajectory radius, so the journey through different cornering, the outside wheel through a long journey, if powered by a shaft to complete the same-sized wheels, two Like speed, but also the same as the diameter of the two wheels when cornering traveled is not the same, it would need to curve inward wheel slippage (do not walk), made turning difficult; to overcome, to improve this problem, the vehicle drive shaft divided into two halves, parted in the middle with "differential" connection, when the vehicle upright with two rounds can be the same driving force, while cornering, due to the differential, the inside of the wheel rotational speed lower than the outside wheel this, to a two-wheel drive vehicle forward while wheel movement from the outside but the inside than the larger purpose.

Two axle shaft is to improve cornering performance and vehicle design.]]>

Since its 2012 launch, China's heavy truck HOWO light truck, with its excellent quality and high speed and efficiency of delivery operations adaptability has taken root in the major courier industry, SF, rhyme, Shen Tong, tact, Debon, excellent speed logistics, Hunan logistics headquarters, Kerry Chase, Stateline, transit express logistics companies have matched HOWO light truck vehicles as courier express delivery business.

China National Heavy Duty Truck HOWO light trucks to "maximize returns - to provide the best logistics equipment" for the idea, according to the mode of operation as well as the different needs of customers provide the best vehicle matching; the pursuit of each client with the most suitable for their own logistics vehicles. Country, four HOWO light truck matching technology advanced and mature and stable Cummins, Isuzu -ISUZU, MAN and other foreign engines, bringing strong power efficient logistics; overall configuration optimization. HOWO light truck solid and durable, the advantage of high-speed stability is highly evaluated by the various bulk purchases Express Company, is rapidly becoming the courier industry force.

Two sessions this year, Premier Li Keqiang made the "Made in China 2025" in his government work report, this plan brewing for years, and now is still being improved. At the China Development Forum 2015 annual meeting, experts and industry insiders believe that this is a good opportunity for Chinese industry to catch up.

Manufacturing country corner overtaking opportunities

As a manufacturing powerhouse, the German government's "Industry 4.0" strategy, many experts, and "Made in China 2025," the same thing, are aimed at a new round of revolution in manufacturing, information technology and traditional industries depth integration.

"China has a unique advantage, we are IT innovation power, is a large global manufacturing country, if we can seize this opportunity, then we may in the past, industry is relatively backward situation, to create a miracle turn overtaking . "China Electronics Technology Group Corporation chairman Xiong Qunli representation.

"By manufacturing the product, and then sell them to foreigners, China and the world economy to make themselves reborn in 1990, China in the global manufacturing output in less than 3%, is now close to 25% of the world 80 percent of air conditioning , 70 percent of mobile phones and 60% of the shoes are made in China. "British" Economist "magazine this year March 14 cover story point to praise the" Made in China. "

Challenges can not be ignored

"We propose a new target for industry, not only provides a good opportunity, there are many challenges can not be ignored." China Aerospace Industry Corporation chairman Lin Zuo Ming said.

In LinZuoMing opinion, the future of at least two major issues need to be resolved. First, under the new manufacturing requirements, to enhance the quality of labor. "In the past junior high school graduates can engage in low-end manufacturing, but in the" Made in China 2025 "under the requirements of some jobs and even college students are not competent." Second, the demand for labor will be reduced, this will bring the possibility of employment.

"Data shows that over the past few years, Chinese enterprises the ability to create value in the fall." China Aerospace Science and Industry Corporation, chairman of the high Hongwei believes that the transformation and upgrading of China's manufacturing industry, especially the need to establish a "synergy" and "share" in the concept of consciousness . He believes that the Chinese people in the past to do things not in the habit of sharing and collaboration, but in the face of competitive pressures in the world's manufacturing industry, need to learn to find their own interests and growth synergies in points.

The whole world is looking forward to a new era

"Prime Minister Li Keqiang" Made in China 2025 ", the specific program, although not yet introduced, but the whole world is looking forward to." Xiong Qunli believe, in addition, the government work report made by the "Internet +", etc., are in It shows a new industrial era is coming.

In fact, some of the changes taking place. According to members of the Management Board of Siemens AG Bole Ren introduced them factories in Chengdu and Shanghai, under the create digital business goals, has been to achieve faster time to market, automated quality control, and many other breakthroughs. The Wuhan plant in the aircraft industry, and a new production line, the original need 6,000 employees, under the new concept, just over 1000.

"China is very fortunate in the time needed industrial transformation and upgrading, ushered in such a new industrial revolution." The former party secretary, deputy director of the Development Research Center of the State Council Chen Qingtai said.

]]>